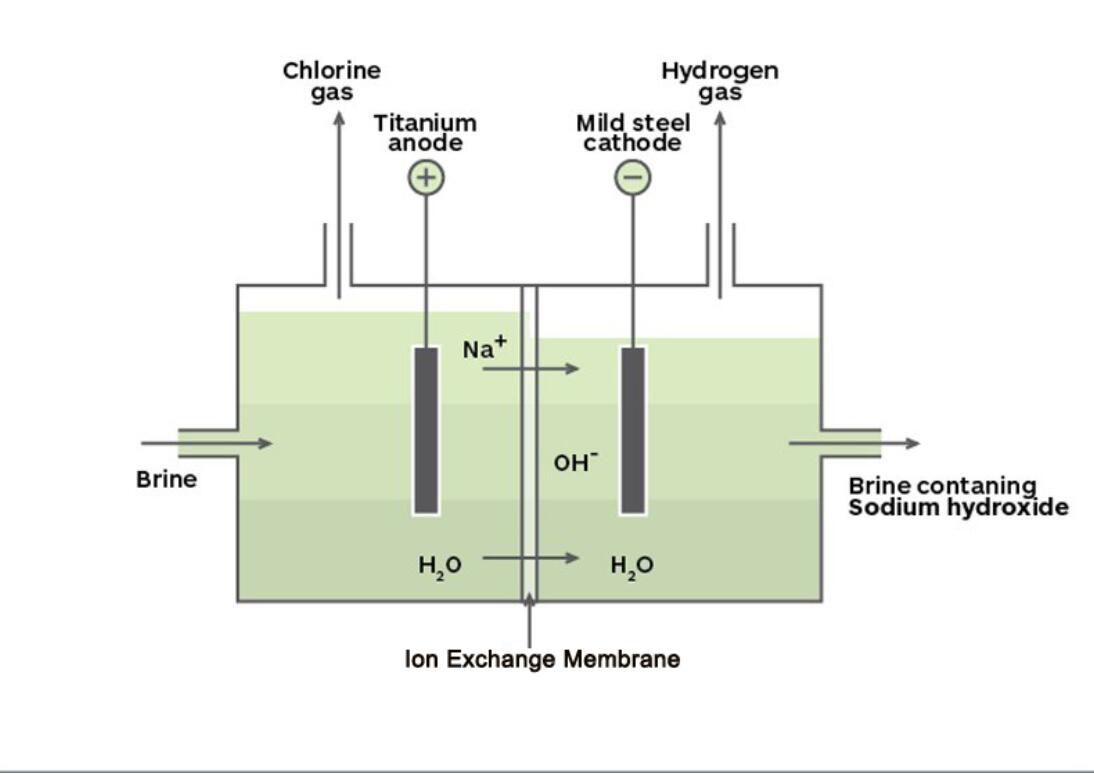

For production of chlorine and caustic by electrolysis, we develop chlor-alkali Ion-exchange membranes which are widely used in chlor-alkali industries, electro-dialysis, recovery of copper from etching solutions, synthesis for gold potassium cyanide , chlorine dioxide, and electrochemical reaction for amino acid. The membrane performs as a conducting separator and solid electrolyte in a variety of electrochemical cells which require the membrane to selectively transport cations across the cell junction.

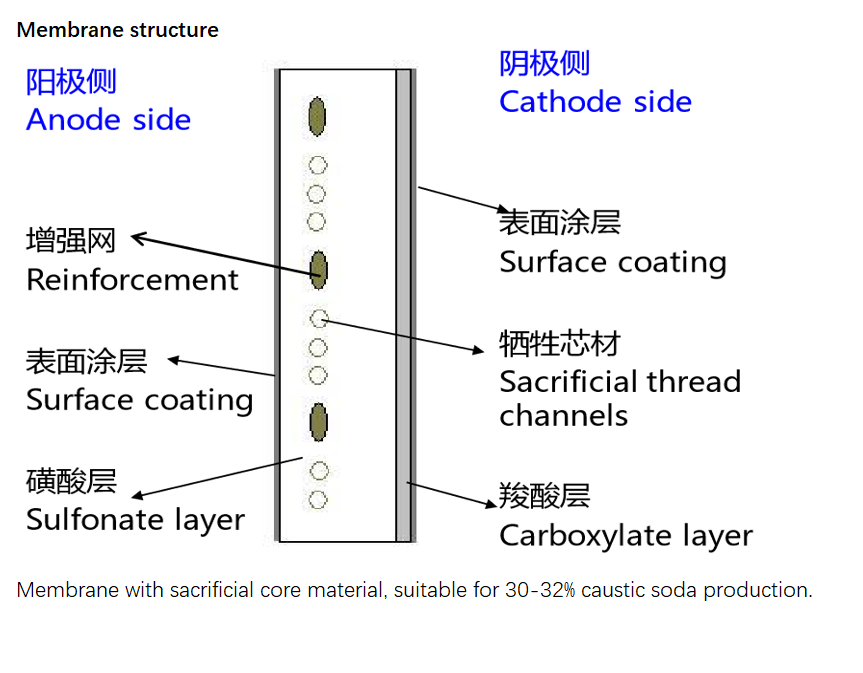

Our chlor-alkali Ion-exchange membranes are reinforced membranes based on chemically stable perfluorosulfonic acid (PFSA) copolymer. Incorporation of the PTFE mesh reinforcement improves the mechanical property of the composite membrane and allows the membrane to restrict its swelling. The membranes show significant improvements in features such as better resistance to chemical attack and longer operating durability under electrolysing cell conditions.

The structure of the membrane:Sulfonate layer and Carboxylate layer

Quality of feeding brine:

No. |

Item |

Specifications |

1 |

NaCl |

300--320 g/l |

2 |

Ca+Mg |

<0.02 mg/l |

3 |

Sr |

<0.05 mg/l |

4 |

Ba |

<0.5 mg/l |

5 |

SiO2 |

<2.3 mg/l |

6 |

Al |

<0.1 mg/l |

7 |

I |

<0.2 mg/l |

8 |

Fe |

<0.1 mg/l |

9 |

Ni |

<0.01 mg/l |

10 |

ClO3 |

<15 mg/l |

11 |

SO4 |

<7 g/l |

12 |

TOC |

<10 mg/l |

13 |

SS |

<1 mg/l |

14 |

PH |

9--10 |

Applications:

Chlor-alkali membrane is produced with sacrificial core material, suitable for 30-32% caustic soda production.Chlor-alkali membrane is suitable for running bars with high current density.

Chlor-alkali membrane has higher tolerance to salt water impurities

Size of the Chlor-alkali membrane:

standard size: 1500*2460 mmThe membrane pieces or rolls can be cut to non-standard sizes, please contact our sales staff for details and availability.

Development History of our Chlor-alkali Membrane: